Interview 1: Bailey, an Ironworker

Bailey is an apprentice with Ironworkers Local 25 in Detroit, MI

Women Who Weld, a 501(c)(3) nonprofit organization that teaches women how to weld and find employment in the welding industry, has launched a new program - Arclight - in which we showcase women who create, ideate, and collaborate across specializations and trades.

Bailey Steele completed Women Who Weld’s Intensive Welding Training Program in July 2018, and landed a job as a production welder at a custom steel packaging company where she became ‘Employee of the Month’ just a few months into her new welding career. After working as a production welder for a year, Bailey was accepted into the Ironworkers Local 25 Apprenticeship Training Program in Detroit, MI. Below is an edited and condensed interview between Samantha Farrugia, the founder of Women Who Weld, and Bailey, a former Women Who Weld participant, in January 2021.

You first reached out to Women Who Weld in late 2017 when you were 18 years old and living at Vista Maria, a nonprofit residential facility for youth. Why were you living at Vista Maria and what sort of resources did Vista Maria provide you with?

The State sent me to Vista Maria because I was having some trouble with my mental health and I was getting into a lot of trouble in school and at home. Vista Maria helped me through therapy and taught me ways to cope with things. They also set you up for life and living; and one of those things is careers, but I had no clue what I wanted to do. So, they helped me get a job at Taco Bell. And then I said, “I'm bored with this, what now?” There are so many cool ladies who work at Vista Maria and one of them, Miss Kay, said to me, “Well, you like being active and working with your hands, so why don't you try welding?” She was the one who told me about Women Who Weld, so I looked it up online and called you. So that’s what Vista Maria does, they set girls up to live their lives.

There are several trade unions engaged in welding, including the Boilermakers, Carpenters, Ironworkers, Millwrights, Pipefitters/Steamfitters, Sheet Metal Workers, Steelworkers, and so on. Why did you choose to become an apprentice with the Ironworkers union?

When I first heard about the Ironworkers, I didn't really know that much about it. A co-worker at my first welding job was leaving to go to the Ironworkers and said I should look into it. I did, and I learned I had to be okay with heights, but I'd never been high up before to even know if I liked heights or not. I thought it was cool to build structures and it would help me fulfill my big dream of welding on the new bridge to Canada. And all I knew was that I wanted to weld, the pay is good, and it's fun. There's also some danger involved and I like that. The other trades are good, but I love ironworking and the adrenaline from it.

For those who are unfamiliar, union ironworkers belong to The International Association of Bridge, Structural, Ornamental and Reinforcing Iron Workers Union; they read blueprints and assemble structural framework, install metal support pieces for structures, and renovate and repair structures. How do you describe your job as an ironworker when someone asks what you do for a living?

When a regular person asks me, I tell them I build anything to do with steel or iron.

What is a typical day like as an apprentice? I imagine it changes day-to-day, but on a typical day, what is it like?

I wake up at 5:10 a.m. and leave the house at 6 a.m. Right now, I’m working on the new Wayne County Jail in Detroit and we start at 7 a.m. Each morning the crew meets and we stretch and flex - it’s kind of like yoga - then we debrief about what we're going to do that day. After that we break off into groups and set up the welding machines and gather everything we need. At that point I start welding and I weld pretty much all day. We pack up about 15 minutes before the end of the day and we go home at 3 p.m.

I'm really curious about this morning yoga routine, how long does that last for each day?

Maybe about five minutes. It's just like basic stretches, I consider it yoga because I can see the similarities in it. I'm sure the guys probably don't think about yoga when they stretch.

And for those who are unfamiliar, a union apprenticeship training program is a supervised method of training apprentices who have little to no experience in the trade. Apprentices earn money while they learn on-the-job, working alongside journeyworkers. Depending on which trade you are in, the apprenticeship training program is usually 4-to-5 years in length. Apprentices must attend classes for supplemental instruction and they do not pay for this training. Additionally, an apprentice’s hourly pay goes up every 6 months, and when they complete the program, they become a master in their trade, also known as a journeyworker or journeyman. Many journeyworkers make six-figures a year and receive benefits like healthcare, a pension and an annuity.

Union apprenticeship training programs can be challenging and competitive to get into. Would you recommend a union apprenticeship training program to someone interested in the trades, and why?

Yeah, I really would recommend it to somebody who wants to get into trades, because the union training is top of the line, they're always on point with their safety and they make sure everybody knows what to do. And the connections you make in the union will help you for the rest of your life. If you're a good worker, you really don't have to worry about work because you’re always going to know somebody else in the union who knows you’re a hard worker and will recommend you for jobs. And that's just something that you only get with the union. So yeah, the training and the connections.

As you know, I present three pathways in welding to Women Who Weld participants: they can choose to pursue a job in welding, a continuing education opportunity, or an apprenticeship training program. I highly recommend union apprenticeship training programs, but my recommendation comes with a caveat, that a union apprentice commits themselves to the trade for at least 5 years, or longer, so it’s important to understand the difference between the trades and if it is the right fit for that individual.

“All I knew was that I wanted to weld, the pay is good, and it's fun.”

Did you find the WorkKeys test or application process for the apprenticeship program challenging? Do you have any advice for someone who is interested in applying to a union apprenticeship training program?

The WorkKeys test is basically like any standardized test. My advice is to just relax. Everybody was really nice at my testing hall and they know people are nervous so they explain everything to you. I would also make sure that you can pass a drug test, because you have to pass to get in.

You have to complete approximately 160 hours of classroom training each year at Local 25’s apprenticeship training center. How often do you attend the classes, how many people are in them, and what are the classes like?

We attend class for one week every three months and my class has about 15 people in it. Half of the week we work in the shop and weld, or learn things like connecting and rod busting. And then the other half of the week we sit in a classroom and the teacher goes over all the homework we had, and we take tests. It's all pretty straightforward, the teachers help us and they are supportive about the tests. That's what I was nervous about, because I'm not a good school person so that’s why I chose to go into the trades. For me, it's much easier than regular school. There is a lot of welding time and they teach you everything, like the fine details of field work.

Can you explain rod busting?

It's basically tying circular metal rods with wire into big squares across an entire floor. This helps to hold everything in place in the event the concrete shifts, it prevents it from crumbling down.

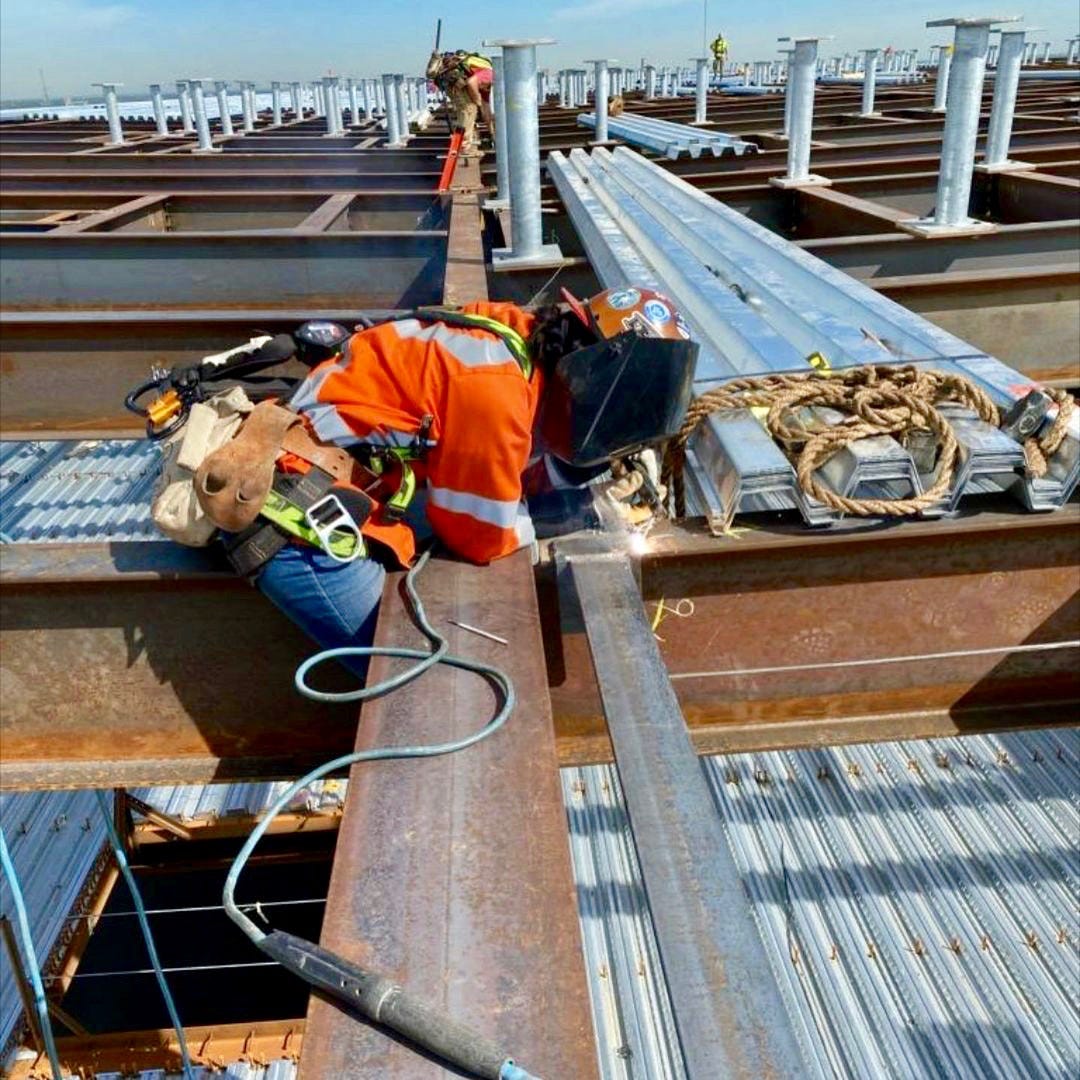

I imagine you are mostly stick/SMAW welding?

Yeah, we mostly stick weld. We also have a few flux-cored and MIG welding machines too. But in the field it’s really just stick welding and some flux-cored welding.

For those who don’t know, SMAW, which stands for shielded metal arc welding – or ‘stick’ for short – is a welding process that can be performed outdoors, and is what most people might conjure when they picture a welder at work: someone wielding a long sparkler. The long sparkler is a flux-coated electrode – the composition of the electrode varies depending on the material being joined together – and as the flux burns, it forms a gaseous shield around the tip of the molten electrode, protecting it and the integrity of the weld from contaminants in the atmosphere. Stick welding is quite different from other forms of welding.

The Ironworkers have a 4-year apprenticeship training program. You have been an apprentice for 1.5 years, so you have 2.5 years until you are eligible to become a journeyworker?

Yes.

Once you’re a journeyworker, how will your day-to-day activities and responsibilities change?

My activities will not change too much, but I probably won't have to fire watch as often and I'll be given more responsibility. But other than that, I think I'll still be welding a lot.

You mentioned your work day usually starts at 7 a.m. Have you had other start times earlier than that?

It's mostly 7 a.m., but I've had 6 a.m. and 6:30 a.m. starts. I like starting at 6 a.m., I think it’s a little better than 7 a.m. actually.

Are you a morning person?

I’m not technically a morning person, but I'd rather get in early and get out early to have some daylight at the end of the day.

You worked until 3 p.m. today and you mentioned you worked until 4 p.m. at another job. Have you ever worked later than that?

Yeah, when I first started as an apprentice, I was doing 7-10s, which means I was working 70 hours a week: 10 hours a day, 7 days a week. I would start at 7 a.m. and leave at 5 p.m.

That is a pretty demanding schedule considering the physical strain from being on your feet all day, moving around a site, lifting heavy items, and operating machinery. And then there is the mental strain from solving problems and overcoming challenges, and having to be aware of your environment at all times to stay safe. It’s strenuous work, both mentally and physically. Were you exhausted at the end of these 70-hour work weeks?

Yes, absolutely.

Additionally, you are often working outside, enduring inclement weather and varying temperatures. Plus, you’re dealing with a lot of heat from welding. Do you get used to working in these conditions?

Yeah, you get used to it. But after a couple months, you get pretty burnt out. And so usually a lot of people take like a week or two off and may go on vacation.

What do you eat for breakfast and lunch on a day like today, for example, to power you through your rigorous work day?

I'm not a breakfast food person, so for breakfast I'll have a couple hot pockets and a protein shake. I'll drink lots of water and coffee too. At lunch, I have a sandwich and some chips and snacks. Sometimes we'll go out to White Castle or something like that. I'm not a super healthy eater. And then for dinner is when I really eat, like last night I ate two chicken chipotle wraps. You definitely have to up your eating game to get all the carbs you need.

What do you like most about being an ironworker?

The freedom you have to make your own decisions on to how to get things done. I also like the adrenaline of it. I think it's so fun to do things that the average person doesn't do every day; go up high and be a little scared but still do it. It’s also just a good environment, the people are so crazy and funny and it's just so different from an average work environment.

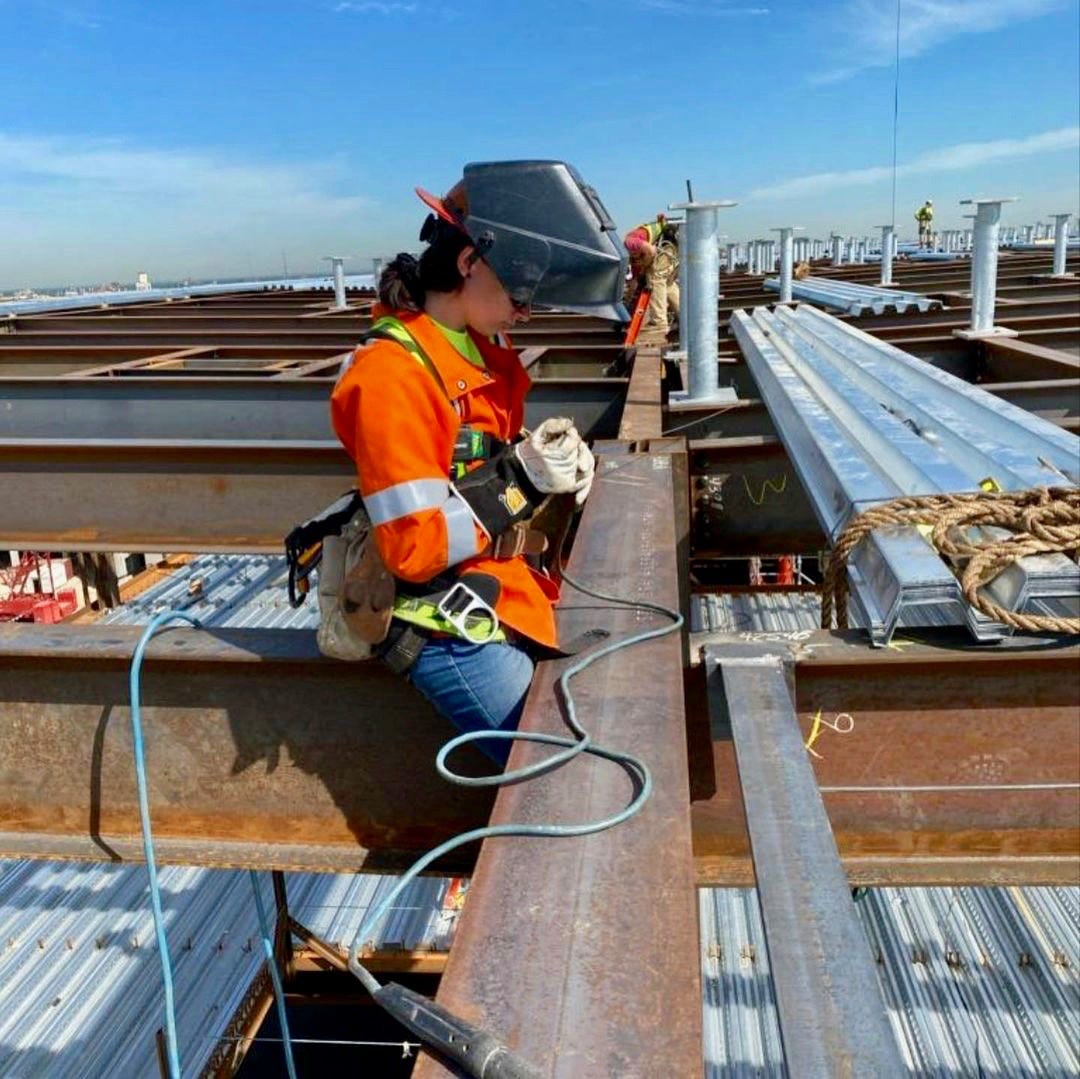

What’s the highest elevation you’ve worked? Was it scary?

The highest so far has been the roof of the 7-story jail. And I wasn't really scared. I didn't allow myself to be scared. Before I went up, one of my co-workers asked me, “Are you scared of heights?” and I told him, “I don't know, let's see.” So, I went up there and I was a little shaky at first. I could tell everybody was watching me really close to see what I was going to do because a lot of people freak out once they're up there. I just stayed calm and didn't think about how high up I was. But once I got used to it up there, I started looking around and thought, “This is not so bad.”

I imagine the views of downtown Detroit are pretty amazing from up there.

Oh, yeah, it's so pretty, especially the sunrise every morning. That's my favorite.

A few months ago, you were featured on Women Who Weld’s Instagram, Facebook, and LinkedIn accounts. What I found really cool were the comments from your current and former colleagues who said you were “an inspiration”, “a role model”, and “one of the hardest workers they’ve worked alongside.”

You seem like a natural leader, you were ‘Employee of the Month’ at your first job as a welder; and your current and former supervisors have told me great things about your work ethic and welding skill. You also mentioned to me in the past that you enjoy public speaking. Do you see yourself becoming a public-facing representative for the Ironworkers one day? Is that something you would be interested in?

Oh, yeah, definitely. I've already been thinking about it. I know I want to be somewhere important, making changes, and have a voice for everyone around me. So yeah, it’s definitely something I've been thinking about.

That's great. Have you had any interactions with the Ironworkers International Leadership Team or, specifically, Vicki O’Leary, the Ironworkers General Organizer of Diversity?

Not any personal interaction, but I participated in a Zoom meeting for all the women in the union about a month ago. It wasn't an interactive meeting, but we watched a really cool video and listened to speakers who discussed their issues, concerns, and some changes in the future. So that was really cool.

The Ironworkers seem to be making a concerted effort to recruit more women. In 2017, the Ironworkers, under the leadership of General President Eric Dean, were the first union in the building trades to enact a generous paid maternity leave benefit. The Ironworkers also hold a semi-annual, 3-week pre-apprenticeship training class in Benicia, CA, for women across the US who are interested in becoming an ironworker. I had a chance to tour the facility and speak with the women in the pre-apprenticeship training class in 2019.

According to the Ironworkers website, there are 120,000 ironworkers in North America and only 2,000 of those ironworkers are women. Additionally, women only constitute 5% of all welders in the United States. Have you ever worked with another female ironworker?

Not on the job, but I do go to school with two women. I’ve been to a few meetings with the other female apprentices in Local 25 to talk and get to know each other. There are 8 new women that I haven’t met yet. I see women from the other trades all the time on the job site and I get super excited!

Do you have advice for women who may be interested in pursuing a career in ironworking, in welding, or in the trades in general?

My advice would be to keep an open mind and try to learn everything you can. And if anybody says anything to you that makes you feel uncomfortable, don't take it. You need to nip it in the bud the first time.

I agree with your advice. I tell Women Who Weld participants to stand up for themselves, and if someone makes an inappropriate comment, let them know firmly that you don't like being talked to that way. I think that is the most effective way of shutting down any sort of problems, especially in the workplace.

Yeah, because I used to do that; I used to just ignore it and then I realized it was taking more of a toll on myself and my emotions than it was anybody else. I had to start speaking up and when I started telling them, “Hey, back off, don't say that to me, please, it’s inappropriate.” Then they would apologize, like, “Sorry, I was out of line.” When I stood up for myself is how it really ended up stopping for me.

It's unfortunate you even have to do that. But, it seems to be the most effective way of making your work experience better. You should be able to break free from work and go home with a clear mind, without feeling uncomfortable or upset from inappropriate comments. At the end of the day, it’s okay to feel physically drained, but you shouldn't feel emotionally drained or afraid to go to work.

“I see women from the other trades on the job site and I get super excited!”

You have worked on some major projects, including the new FCA Mack Engine Plant, FCA Warren Truck Assembly Plant, DTE, and the new Wayne County Jail – what exactly did you do on these jobs? Why did they need ironworkers for these projects?

At the Mack and Warren plants, they were remodeling and building a whole bunch of new buildings. We were there to erect steel, weld, and put in elevator shafts. At DTE, they were redoing their big truck parking. They have garages and we had to cut out all the columns that the garages were on and weld plates onto them, and then weld support so they could lift the columns up – without the garage falling down – and allow them to lay new concrete. And at the jail, we're building the entire complex. We erected the building and now we're working inside. Recently, we have been installing hurricane clips, which are metal clips we attach to the beams for extra support. And now we are welding the jail cells.

And who is your employer?

I’ve been with Barton Malow for a year now, and before that I was with Aristeo Construction for about 5 months.

Do you read blueprints and welding symbols in order to figure out what you have to do for the day? Or does the foreman read the blueprints and then tell you what to do?

Yeah, I do read the blueprints. You can rely on the foreman to give you directions from the blueprints, but you should take time to understand the blueprint. If you don’t understand something on the blueprint, you can ask the foreman what it means. I've gotten really good at reading blueprints because I'm always asking, “What does this mean?” or “Where are we at right now?”

That’s great you take the initiative to read the blueprints to understand what you're building. I’m sure it makes you more efficient and effective on the job, and an asset to the team.

You’re only 21 years old, what are your future career aspirations?

Well, I've thought a lot about that, and I'm not exactly sure, but I have a lot of ideas and options that I want to explore. I know I want to be a leader within the Ironworkers. So, I want to see where that takes me. I really just want to do anything that will let me travel all over. And the Ironworkers will let you travel anywhere to work.

If you were not an ironworker, what career path may you have chosen?

I used to want to be a flight attendant, that also has to do with travel. So that would probably be what I would be doing if I wasn't an ironworker.

If you could travel anywhere, where would you go and why?

Right now, my answer would be Paris, because I just think it's so beautiful there and if they ever do any work or repairs on the Eiffel Tower, I would love to do that. So that would be my reason to go there.

Wanting to work on the Eiffel Tower - the largest structure made of steel in the city - is an incredible reason to go to Paris! I visited Paris several years ago and took the elevator to the top of the Eiffel Tower. The best time to go is just before sunset so you can see the city under sunlight and then watch the sun set. The view is amazing!

Wow, that's so cool. I can’t wait to go!